Wecon high-speed cartoning machine is an automation equipment that can efficiently and quickly load products into cartons. It has significant advantages in improving production efficiency, reducing labor costs and ensuring packaging quality, which can be widely used in pharmaceutical, food, cosmetics and daily necessities industries.

In the process of medicine production, the cartoning machine can quickly and automatically load the medicine and instructions into the carton to complete the sealing. In the pharmaceutical industry, this protocol complies with GMP (Good Manufacturing Practice of Medical Products) to ensure the safety and quality of the product;

Introduction

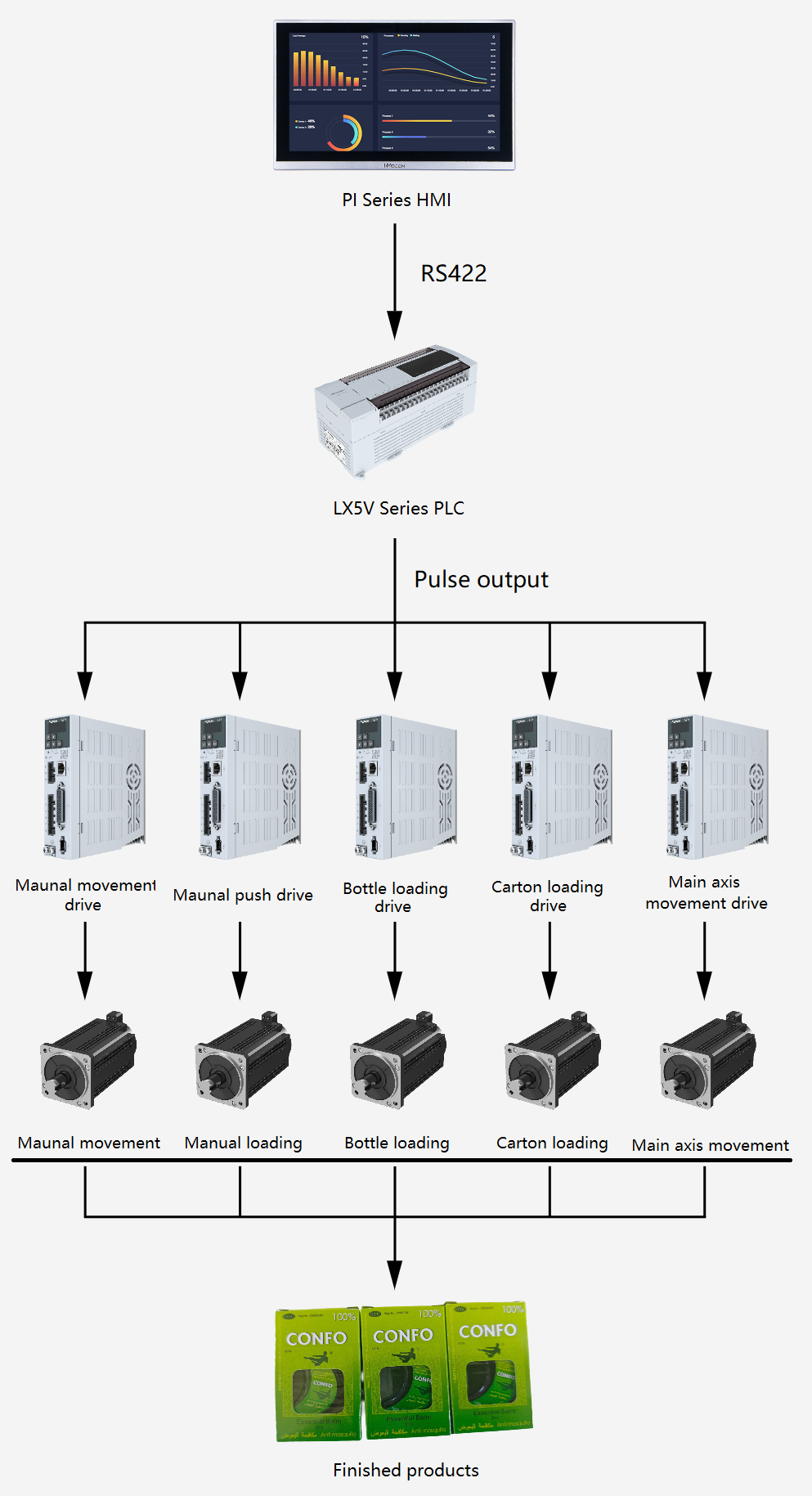

01 Solution Configuration

The integration solution of Wecon high-speed cartoning machine is equipped with Wecon PI series HMI, LX5V series PLC, and VD2 series servo system, which has the characteristics of high speed, high precision and strong integration.

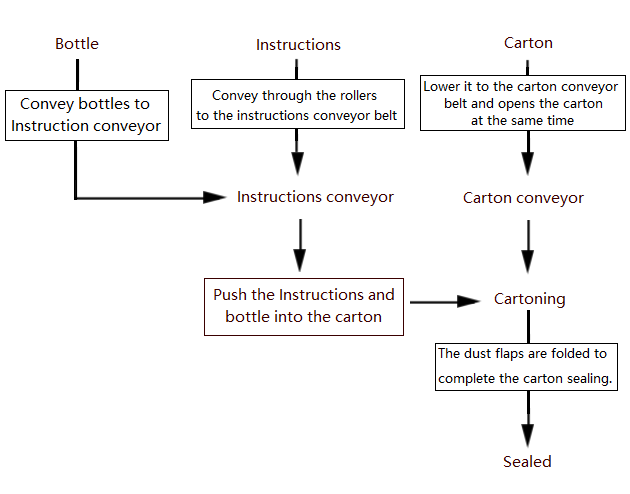

02 Cartoning machine process

1. Bottles and instructions feeding

The instructions enter the conveyor belt through the roller, and at the same time, the medicine bottles that are labeled after the labeling machine also enter the instructions conveyor belt, and one instructions is matched with one medicine bottle;

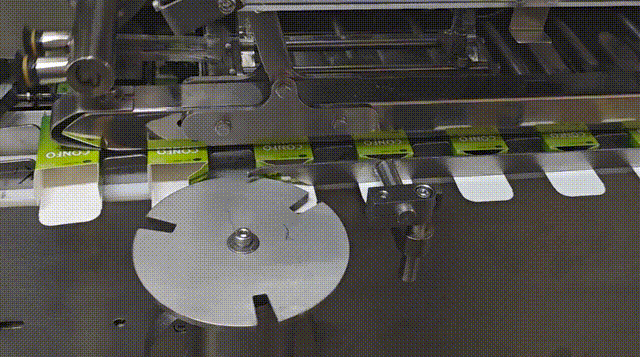

2. Carton loading

A vacuum nozzle catches a carton, lowers it to the conveyor belt and opens the carton at the same time.

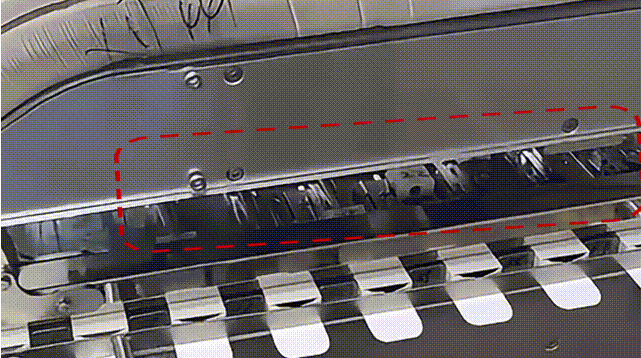

3. Cartoning

Pushing mechanism pushes the medicine bottle and the instructions into the carton to complete the packing.

4. Sealing

The dust flaps of the carton are folded by the carton sealing mechanism, and the tuck flap is inserted into the carton to complete the carton sealing.

5. Finished product display

3. Advantages

Production capacity enhance 300%

01 Improve production efficiency

Quick cartoning: It can complete the packing of a large number of products in a short time, and greatly increase the output of the production line;

Continuous production: The equipment can run stably for a long time, reducing the downtime of the production line and improving the overall production efficiency.

02 Reduce operating costs

Reduce labor costs: Automated cartoning reduces reliance on manual operations, reducing labor costs and related administrative expenses;

Reduce the error rate: Automation operations reduce human error and reduce rework and waste costs due to packaging errors.

03 Improve product quality

Consistency and accuracy: Automated cartoning ensures consistency and precision in the packaging of each product, improving the overall quality of the product.

04 Comply with industry standards

GMP: In the pharmaceutical industry, this solution complies with GMP (Good Manufacturing Practice of Medical Products) to ensure the safety and quality of the product;

Other industry standards: There are similar quality management practices in the food, cosmetics, and electronics industries, and automated cartoning helps businesses comply with these standards and become more competitive in the market.

Applications