Edge banding is a technological process in the furniture production process. It is to bond edge banding strips to the edge of furniture boards to cover the exposed cutting surface of the boards, improve the aesthetics of furniture, and enhance its durability and environmental protection.

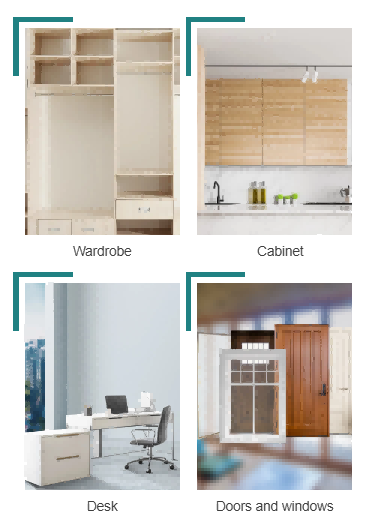

Woodworking edge banding is often used in various furniture manufacturing, such as cabinets, bookshelves, tables, etc. It is an indispensable process in furniture production. The quality of edge banding directly affects the quality and service life of furniture.

A good edge banding process is inseparable from high-precision and high-speed electrical solutions. For enterprises, choosing the right solution can not only improve production efficiency, but also ensure the consistency of product quality and environmental protection, ultimately bringing stronger market competitiveness to enterprises.

Introduction

01 Configuration

The overall solution of Wecon fully automatic edge banding machine is equipped with Wecon PI series HMI, LX5S PLC, and LX3V expansion module. It has the advantages of wide processing size, high processing accuracy and stable processing effect.

02 Edge banding machine process flow

1. Loading

The processed boards are conveyed to the edge banding machine, ready to execute the edge banding process.

2. Pre-milling

The edges of the boards are pre-milled before gluing to remove any burrs or irregularities that may be present, ensuring that the edge bands will fit better.

3. Gluing and feeding/cutting

Apply glue evenly on the edge of the board, send out the edge band at the same time, and automatically cut the strip according to the size of the board.

4. Alignment

Trim the front and back portions of the edge band so that it is precisely aligned with the edge of the board.

5. Roughing/refining

Trim the edge bands to fit perfectly with the boards, ensuring smooth and flat edges.

6. Tracking unit

Track the shape and position of the board in real time, ensuring that the position and bonding effect of the edge band are up to the expected standard.

7. Edge scraping

Scrape off uneven parts on the edge of the edge band, ensuring that the edge is neat and beautiful.

8. Polishing

The edge banding part is polished to enhance the smoothness and aesthetics of the surface.

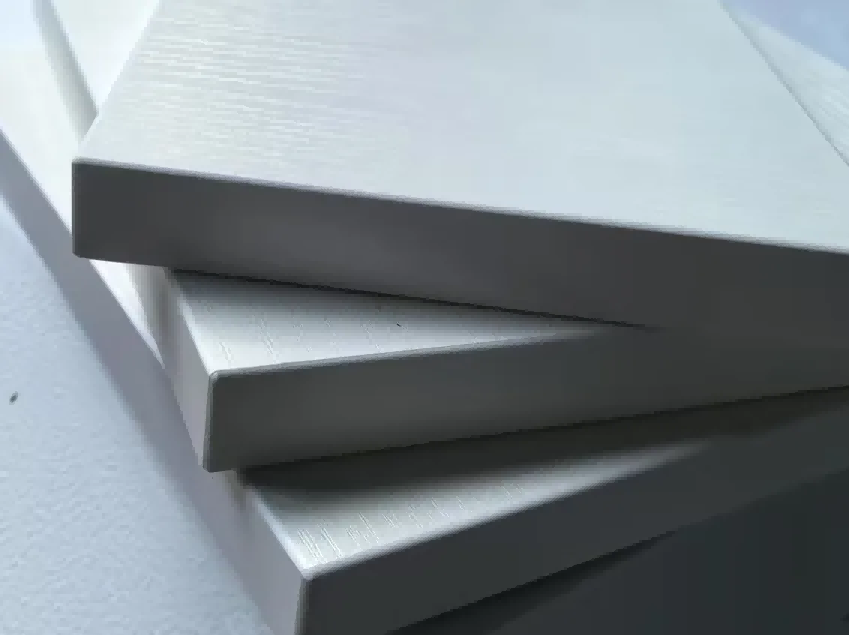

9. Finished product display

Project screen

Advantages

1. Improve production efficiency

The high efficiency and automation degree of this scheme reduce the demand of manual operation, reduce the frequency of machine adjustment, increase the continuous working time of the machine, improve the production efficiency, and realize lower production cost and higher profit margin.

2. Improve product quality

Through the process steps such as refining and edge scraping, the edge band is ensured to be neat and beautiful, and the unevenness or defects that may occur in manual operation are avoided. This refined treatment makes the edges of the finished product smoother, which improves the overall aesthetics and the market competitiveness of the product.

3. Shorten production cycle

After the edge banding is completed, the subsequent process processing can be carried out immediately without waiting for the drying, which significantly shortens the production cycle, optimizes the production process management and improves the capacity utilization rate of the factory.

4. Provide more environmentally friendly production methods

The precise edge banding process can seal the cutting surface of the board, prevent the release of harmful gases (such as formaldehyde) inside, and improve the environmental protection of furniture products; At the same time, it provides enterprises with more environmentally friendly production methods, so that products meet environmental protection standards.

5. Wide applicability

This solution can handle the edge banding of different sizes of boards from cabinets to baseboards. This extensive coverage of edge banding sizes enables enterprises to serve a wider customer base, expand their business scope, meet customized and standardized production needs, and gain more market opportunities.