Background

The stone multifunctional all-in-one machine evolved from the traditional infrared bridge cutting machine and is mainly composed of the cutting knife set, stone conveyor table, and the frame.

The machine can cut regular graphics and process some specific occasions, such as stoves, dining tables, etc.

WECON Solution

Device list:

MC200-0808MT*1

X/Y axis VD3E-016SA1G*2

Z/A/C axis VD3E-014SA1G*3 VB-4T7R5GB

Function:

Regular graphic cutting

Track editing and chamfer settings DXF import and profiling cutting Camera calibration

Board grinding

Debugging Steps

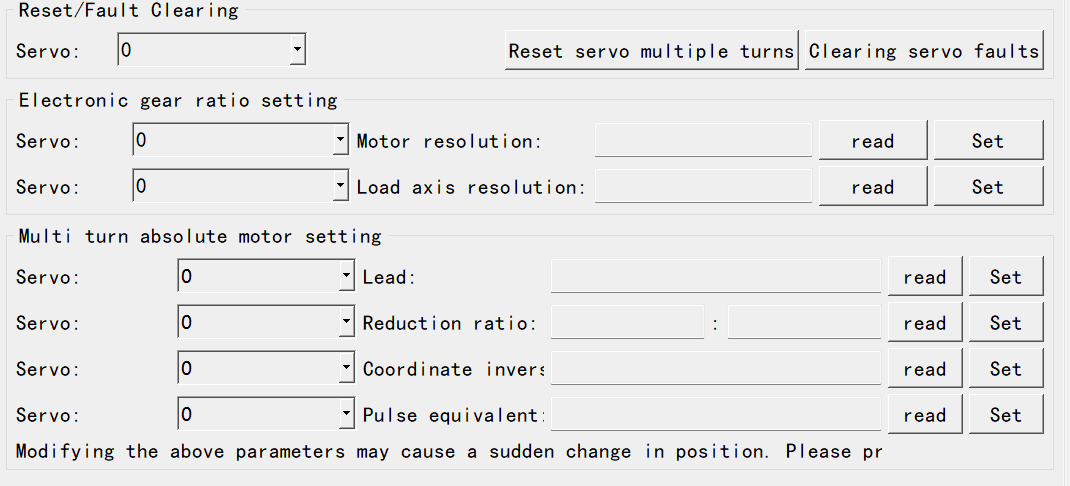

1.1 Pulse equivalent setting

Set the lead and reduction ratio of each axis, and the system automatically calculates the pulse equivalent.

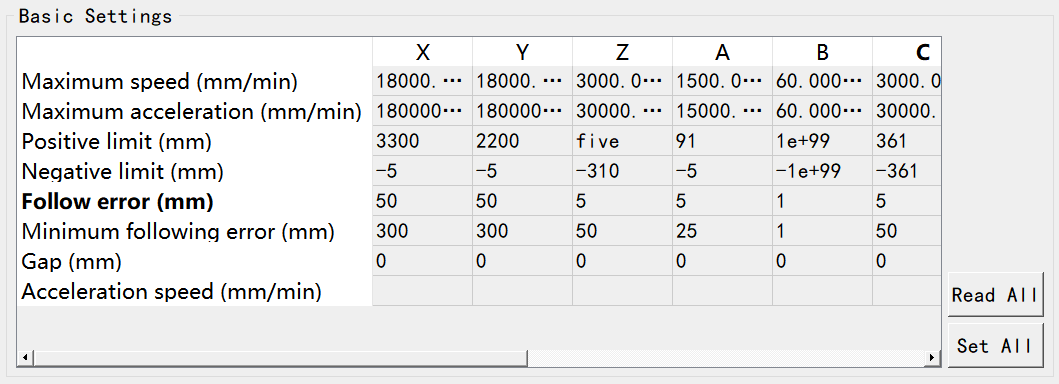

1.2 Mechanical calibration

1.Use equipment such as a level instrument to adjust the mechanical structure to ensure that the XYZ axes are perpendicular to each other and the accuracy of AC axis at 0°.

2.Calculate the pulse equivalent according to the actual movement distance of the XYZ axis

3.Set the origin of each axis (clear the servo multi-turn position)

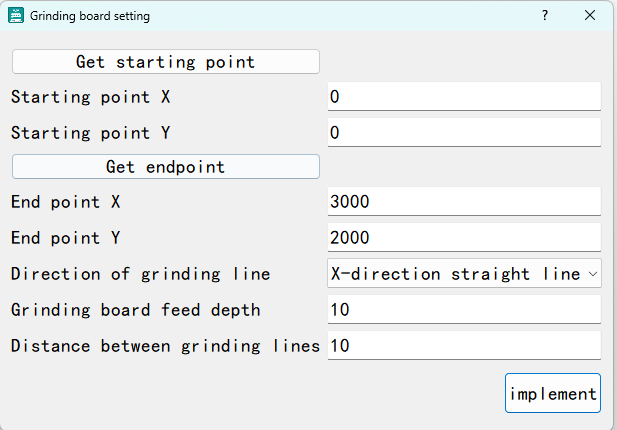

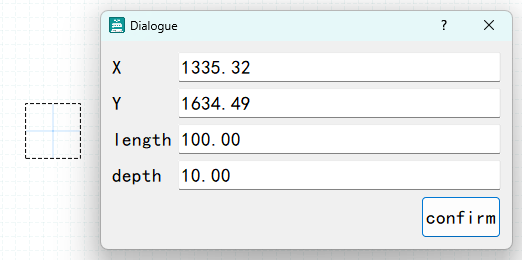

1.3 Planed board

Set the starting point, end point, infeed depth, separation distance to process the table.

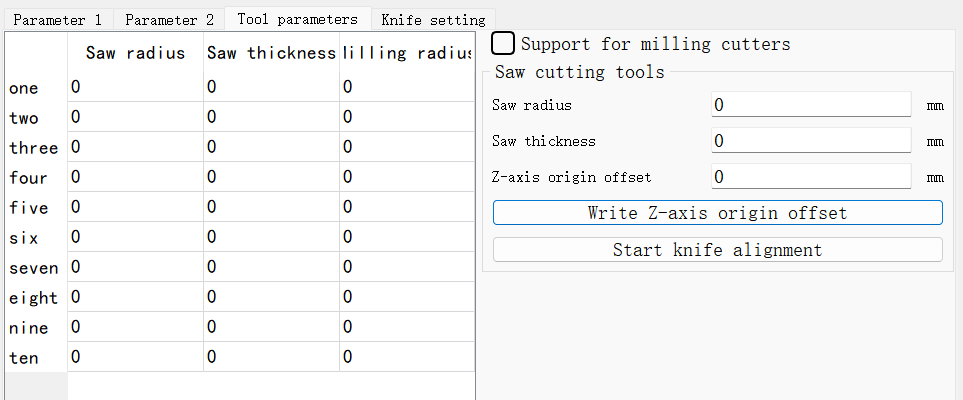

1.4 Cutter parameter setting

Configure radius and thickness for different tools and save as templates.

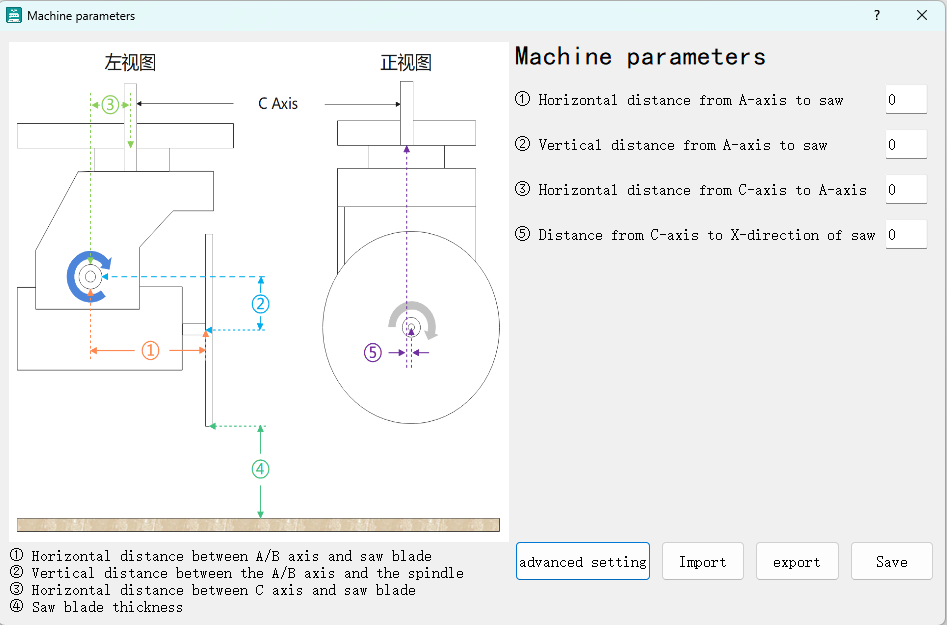

1.5 Machine head parameter setting

1.6 Cutting test

First perform a cutting test on conventional graphics (not involving A-axis chamfering). If the accuracy is OK, it means that the XYZ axis calibration is successful.

Then perform a cutting test on circular sectors and other graphics (designed A-axis). If the accuracy is OK, it means the AC-axis calibration is successful.

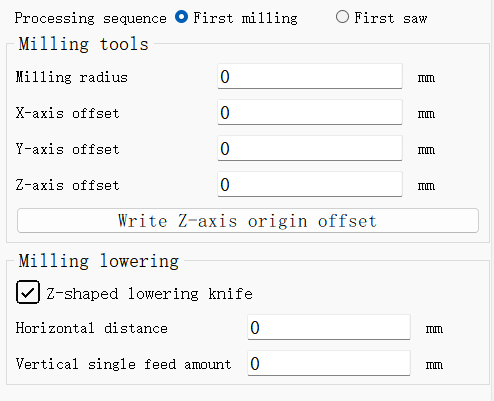

1.7 Milling cutter configuration

Set the processing sequence of the milling cutter and saw blade, the radius, thickness and other parameters of the milling cutter, as well as the offset of the XYZ axis.

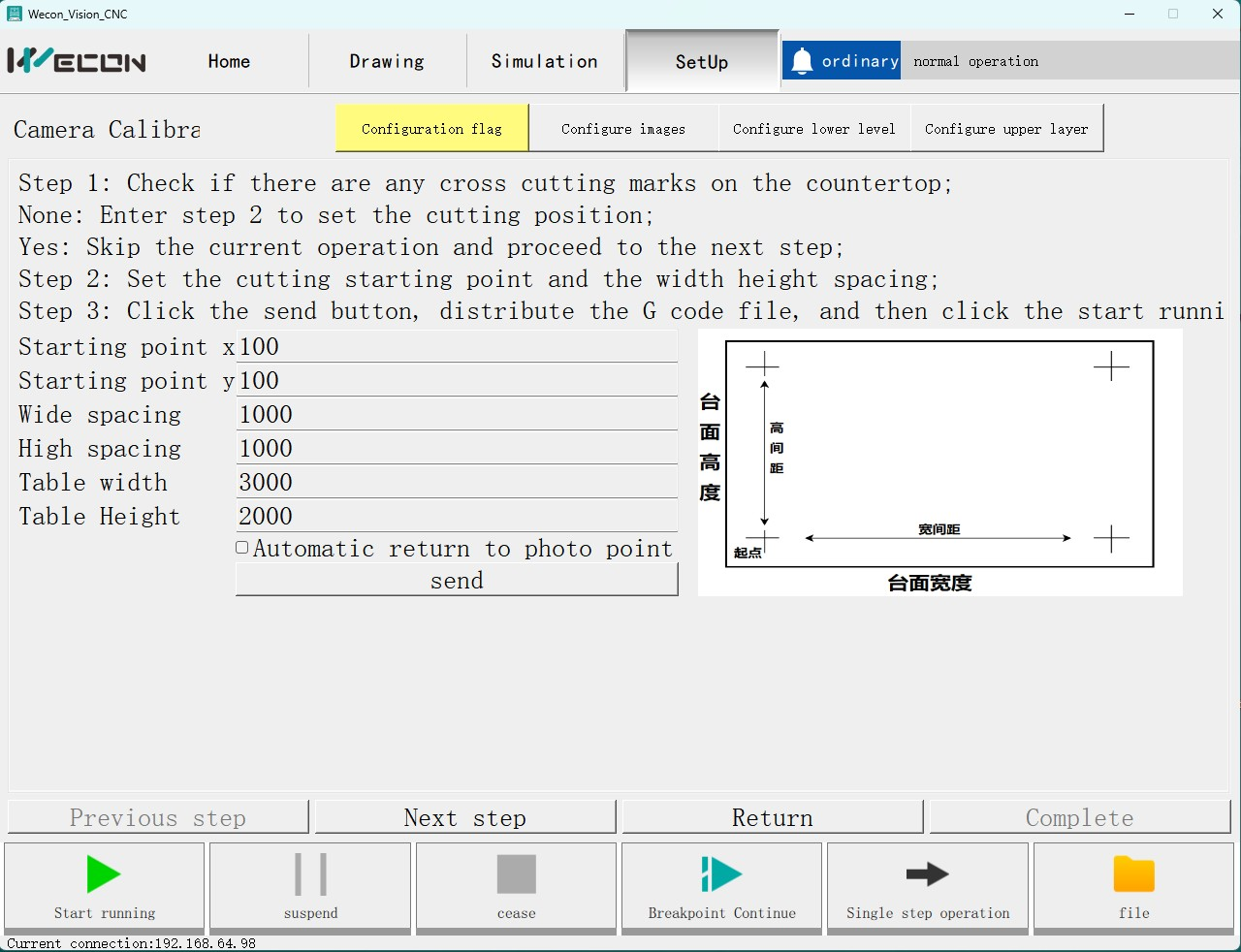

1.8 Camera calibration

Calibrate according to the software prompts, with a total of four major steps and 14 small steps.