As an automatic continuous packaging equipment, pillow packaging machine is widely used in automation production lines in food, medicine, daily necessities and other industries. In order to meet the market's increasingly complicated requirements, Wecon has specially launched a three-servo pillow type machine solution.

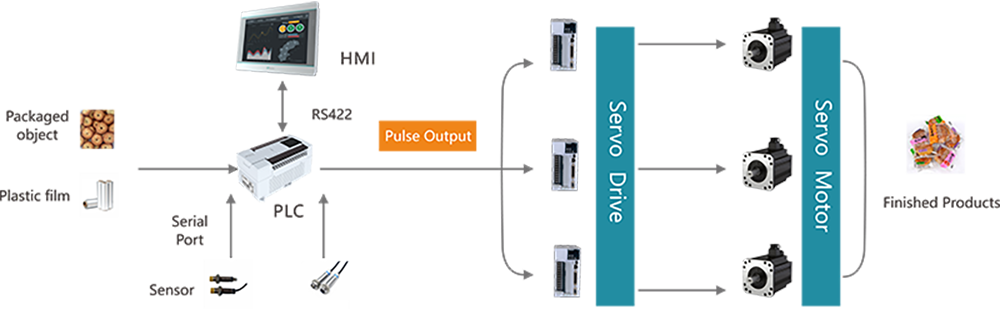

Equipped with three major products: PLC, servo system, and HMl from Wecon, this system is stable, ensures bid tracking and the accuracy of bag length, and has complete functions.

Take food packaging as an example:

Single cutter: 200 packs/minute (double cutters): 400 packs/minute (three cutters): 600 packs/min Packaging precision: ±0.5mm

Take the belt packaging machine as an example: The maximum can reach 150 packs/min.

PS: The above-mentioned packing speed is related to machinery and bag length.

Advantages

One machine for multiple purposes

l Can switch between belt machine and chain fader machine;

l It can switch between fixed length and indefinite length modes of belt.

Prevent cutting materials

l Anti-cutting is realized according to the photoelectric sensor signal; The equipment can make the cutting reverse action.

Support multiple languages

l Supports Chinese, English, Spanish, Russian, Italian, Korean, Turkish, Japanese, Arabic, French and other languages.

Prevent empty package

l For chain model: If the material is empty in the conveying part, the film feeding cutter will automatically stop to prevent the product from being empty.

Film anti-burning

l For belt models: During the production process, if no material enters, and the cutter will automatically stop in the open position to prevent burning the packaging film.

USB drive download function

l Using Wecon PLC and HMI, you can download programs from USB drive, update the system, and facilitate customer process improvement