INDUSTRY BACKGROUND

Pad printing machine is a kind of printing machine, suitable for plastics, toys, glass, metal, ceramics, electronics and so on. As the market scale of pad printing machines continues to grow, pad printing companies are facing fierce market competition and the continuous squeeze of profit margins. Improving production efficiency, reducing costs, and realizing high-quality printing are the fundamental way out for the development of pad printing enterprises.

Program introduction

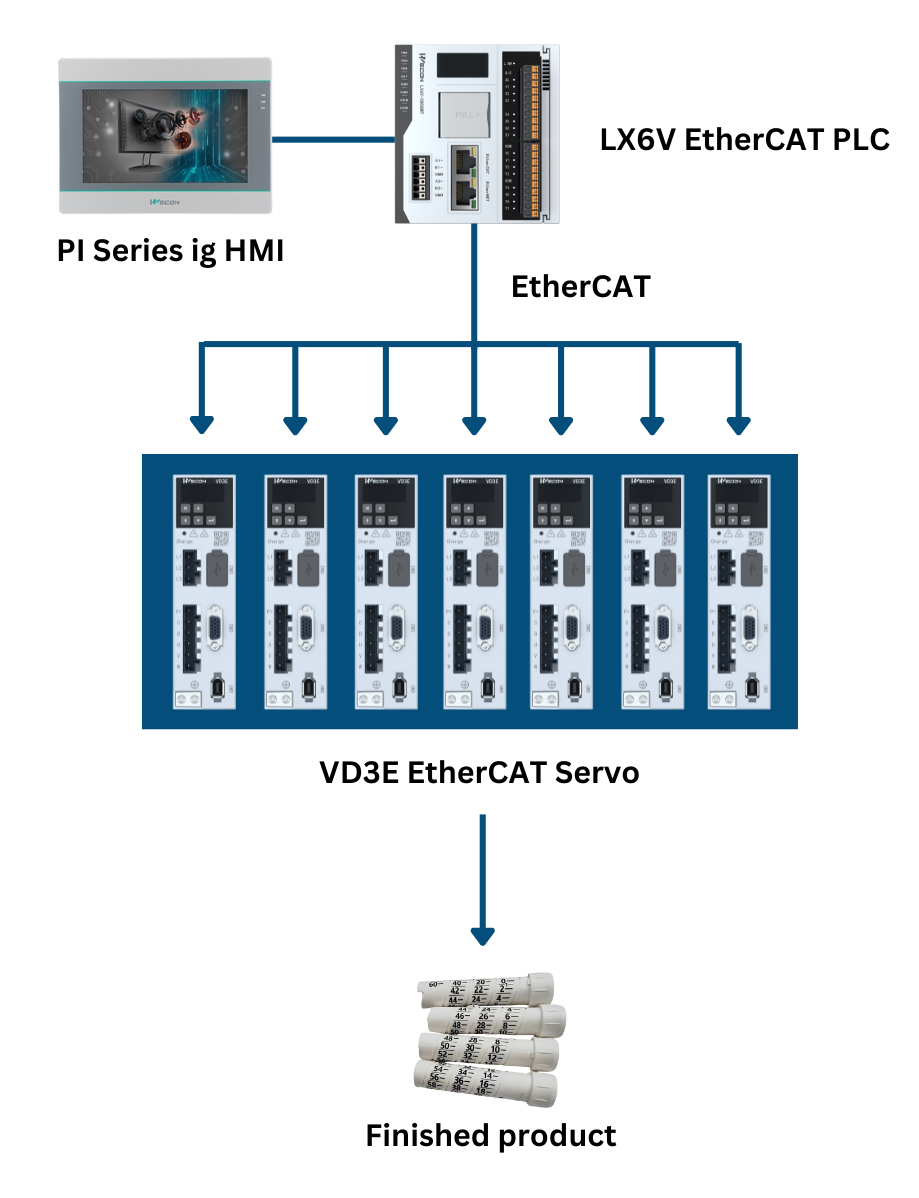

Wecon four-color shuttle pad printer bus control scheme, equipped with Wecon's advanced LX6V Series Bus Type PLC, Wecon PI3000ig series HMI, and Wecon VD3E Series Servo Driver. With strong stability, fast speed and high precision, it can be applied to various production scenarios, meet various printing needs, help users produce efficiently, realize truly automated printing, reduce costs and increase efficiency.

Solution topology

Advantages

Simple wiring

The bus scheme has simple wiring, saves space, and is convenient for system expansion, update and flexible configuration.

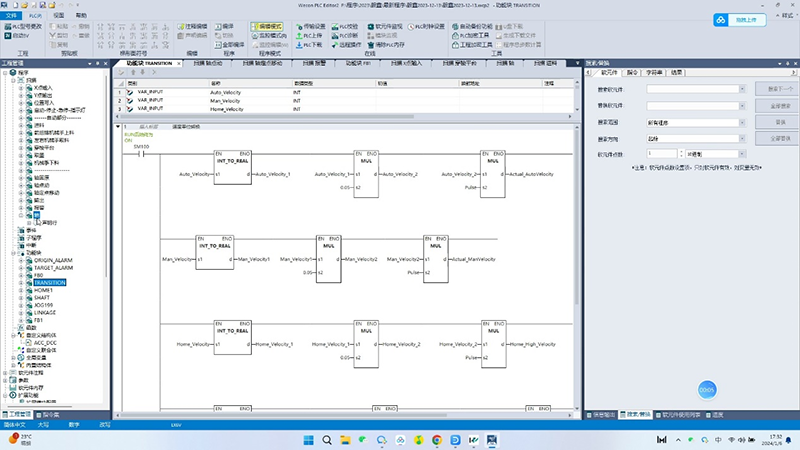

Modular design

FB block can be called for many times, which reduces repeated codes, facilitates personnel debugging, and reduces maintenance workload.

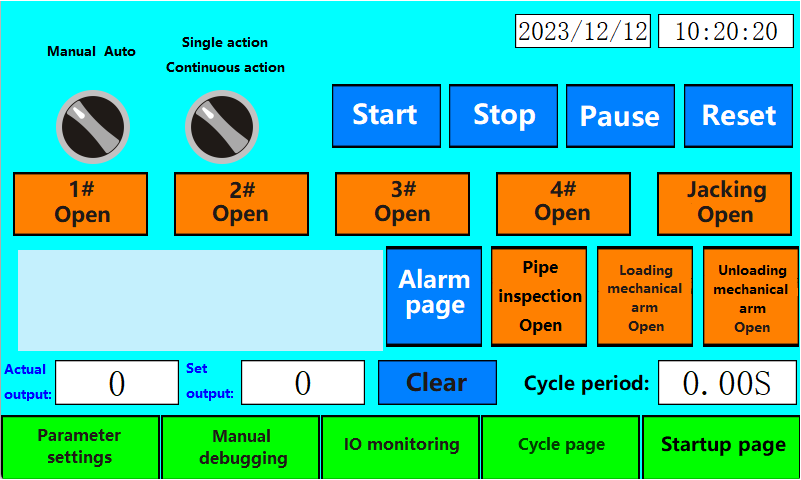

Easy operation

The work station can run separately, and corresponds one-to-one with the screen, which is quick to get started, easy to operate and reduces the cost of manual training.

Safe and reliable

If the machine is abnormal or faulty, the alarm system will respond in time to protect the safety of operators and machine.

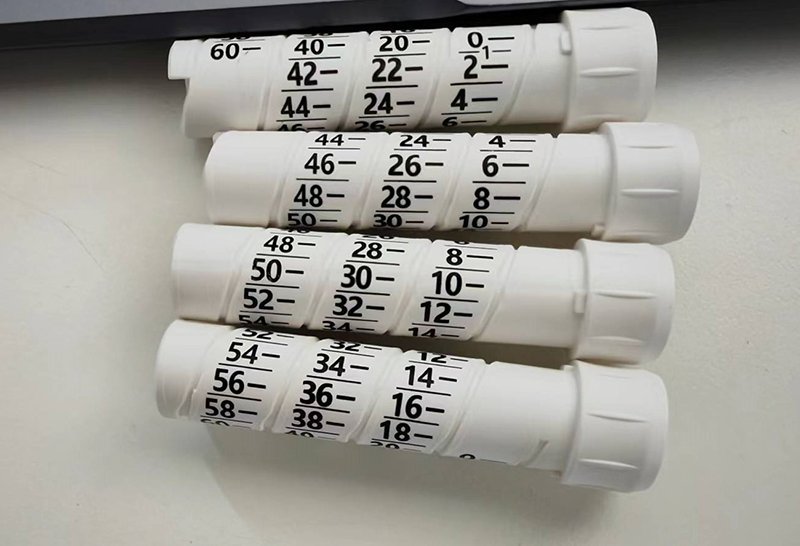

Finished product