In the wood production process, carpentry and polishing are necessary processes. Carpentry operations produce a large amount of dust and shavings; sanding operations produce fine dust and are difficult to collect. In order to reduce the waste of resources, prevent environmental pollution, protect the health of workers and improve product quality, these processes must have dust collection and purification equipment - dedusting systems.

The dust generated during the wood production process passes through the corresponding dust collection hood, air valve, branch pipe and other devices, and enters the main air duct under the suction of the fan, and then enters the dust collector together. After being processed by the dust collector, the purified air is discharged to the outside to meet the standards. VB frequency converter is mainly used to control fans to achieve stepless speed regulation.

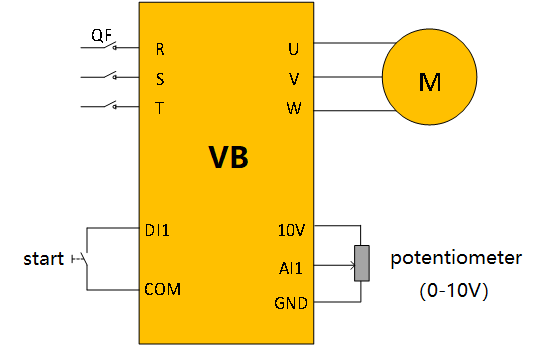

External terminal control and potentiometer are required to control the start, stop and speed of the fan respectively.

The inertia of the fan is large and the time interval between start and stop is short. It is necessary to maintain a smooth transition of the start and stop process.

| Parameter | Description | Set Value | Remarks |

| F0.01 | Start/Stop Order Source | 1 | DI Terminal(External Switch) |

| F0.03 | Frequency Source | 2 | AI1(External Potentiometer) |

| F1.00 | Startup Mode | 1 | Speed Tracking |

| F1.01 | Speed Tracking Option | 2 | Tracking from Maximum Speed |

| F1.02 | Tracking Speed | 1 | Slower Tracking for Large Inertia |

| F1.10 | Stop Mode | 1 | Free Stop |

| F4.01 | Torque Boost | 0.5 | Smaller Boost for Large Inertia |

| F5.00 | DI1 Option | 1 | FWD Run |

VB has digital input and analog input functions, and can be connected with external start and stop buttons and potentiometers to control the VFD to meet system requirements.

VB adopts V/F control mode and adjusts the motor speed instead of adjusting the baffle and valve to achieve the purpose of energy saving. According to calculations, it saves more than 27% of electricity below 45HZ.

| Frequency(Hz) | 50 | 45 | 40 | 35 | 30 | 25 | 20 | 15 | |

| RPM(%) | 100 | 90 | 80 | 70 | 60 | 50 | 40 | 30 | |

| Pressure(%) | 100 | 81 | 64 | 49 | 36 | 25 | 16 | 9 | |

| Head(%) | 100 | 81 | 64 | 49 | 36 | 25 | 16 | 9 | |

| Flow(%) | 100 | 90 | 80 | 70 | 60 | 50 | 40 | 30 | |

| Power(%) | 100 | 72.9 | 51.2 | 34.3 | 21.6 | 12.5 | 6.4 | 2.7 | |

| Saving Rate(%) | 0 | 27.1 | 48.8 | 65.7 | 78.4 | 87.5 | 93.6 | 97.3 | |

| Head(m) | 150 | 121.5 | 96 | 73.5 | 54 | 37.5 | 24 | 13.5 | |

| Flow(m³) | 2000 | 1800 | 1600 | 1400 | 1200 | 1000 | 800 | 600 | |

| Power(kW) | 110 | 80.19 | 56.32 | 37.73 | 23.76 | 13.75 | 7.04 | 2.97 | |

The VB adopts the free-stop option and the speed tracking startup mode, which can enable the fan to start and stop switching in a short time, and the entire process is smooth and fault-free