Introduction

The tile press instrument may also be referred to as a roll type cold bend forming machine, which uses a metal plate and a metal strip to bend the flat plate and process it into a desired shape.

In the past, the device used the encoder to reach the position, and after the feeding was stopped, the punching and shearing operations were performed, and the efficiency is relatively low. The program adopts the method of non-stop feeding to punch and cut.

Process requirements

The main feed shaft of the tile press machine does not stop during the punching and shearing. The pitch, the number of holes and the length of the sheet can be set on the formed sheet. The main feed shaft speed should be greater than 30 meters per minute, the plate length error and the hole distance error shall be less than 1mm. The feeding shaft can be stopped at any time, and can continue to run at the stop position after starting again.

Program

The control system mainly uses two units of LEVI-700EL and two units of LX3VE-1412MT4H.

The brief scheme is as follows: the punching and shearing sections are separated by two sets of PLC and touch screens, which is convenient to use separately. The punched portion uses a non-periodic mode due to the difference in size, and the external signal is activated by high-speed counter comparison. The cut portion initiates an external signal through an external sensor and high speed count comparison.

Advantages

1. The new system has better efficiency compared to the previous stop & cut method.

2. Use 2 sets of equipment could be easier to running independently and produce different products.

3. Through data processing, even if the power is turned off, the device can continue to run after power-on, without starting from beginning.

Program Introduction

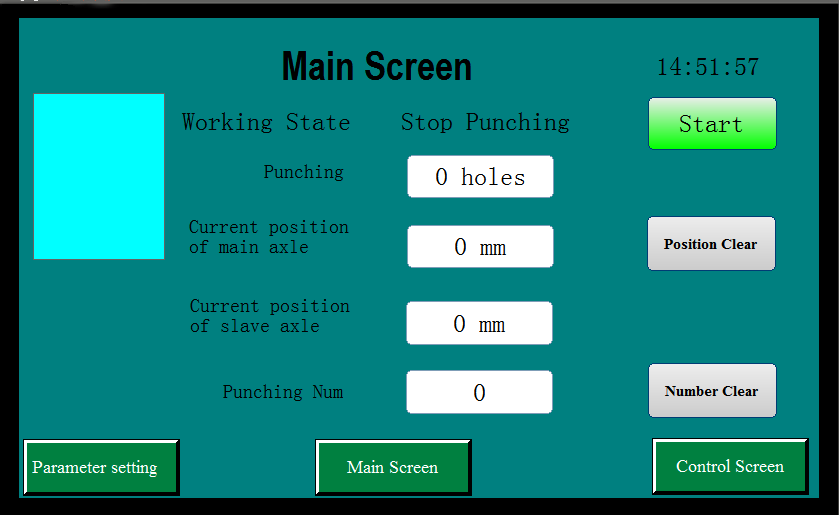

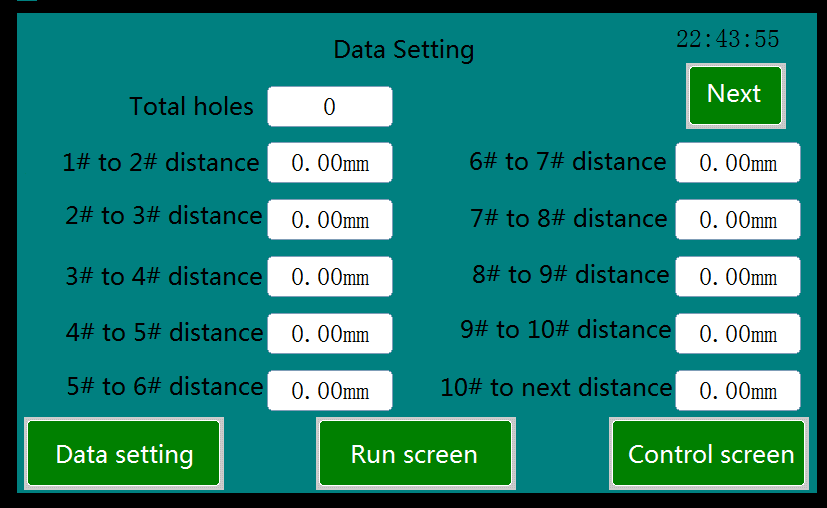

HMI program: running screen, data setting, system setting, etc.

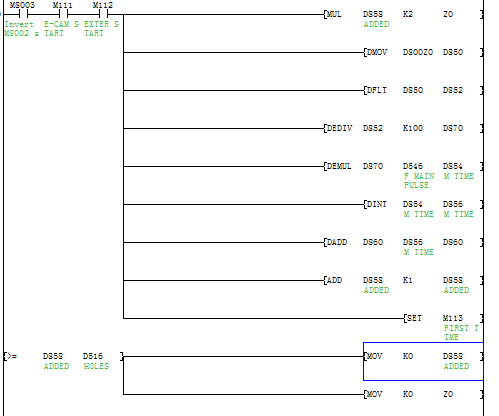

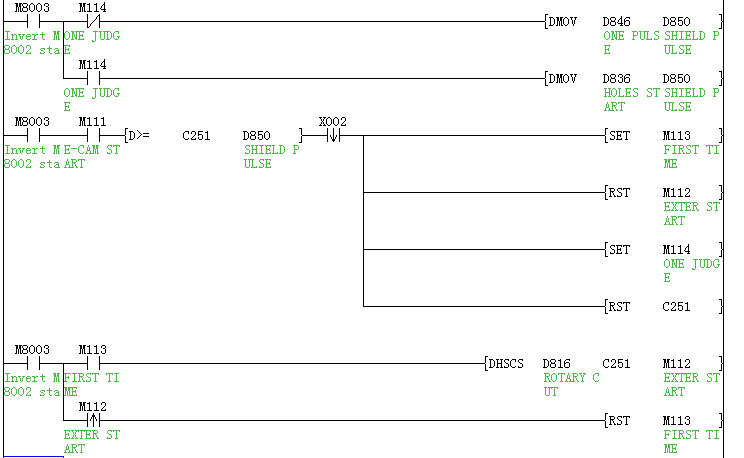

Part of PLC program:

Punching - data processing

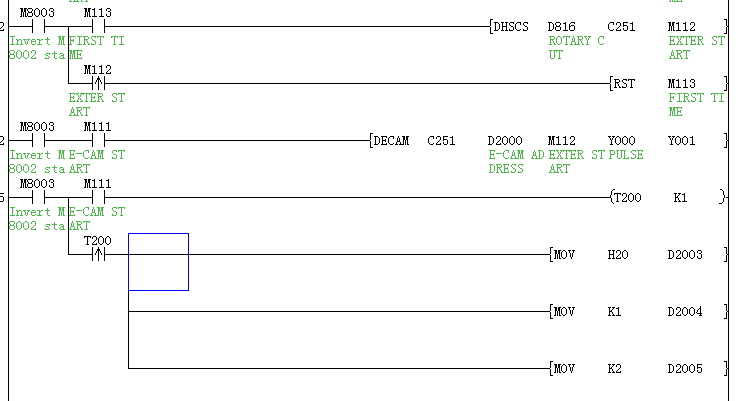

Punching - E-Cam start running

Cutting - data processing

Punching – E-Cam start running

Summary

1. The precision and speed of the punching part of the system meet customer requirements, and the speed is affected by the number of holes on a single plate and the operating time of the hydraulic cylinder.

2. The cutting part of the system can meet the requirements of the customer. In order to make the punching and cutting independent, an external sensor is used, and the speed is affected by the scanning cycle, and the parameters can be corrected by correcting the parameters.

3. This project can produce different sizes plates by modifying the parameters.

Pictures