Project Introduction

"Bomba de agua" es una máquina que transporta líquido o presuriza líquido. Se puede ver en todas partes en nuestras vidas. Se utiliza principalmente para el suministro de agua urbana, sistema de alcantarillado, sistema de conservación de agua agrícola, sistema de central eléctrica, sistema químico, etc. En la actualidad, la mayor parte de la gestión de las bombas de agua es operada por patrullas manuales, lo que requiere mucho tiempo y no puede implementarse a tiempo. Una vez que ocurre una falla, el problema no se puede eliminar la primera vez y el suministro normal de agua no se puede restaurar rápidamente.

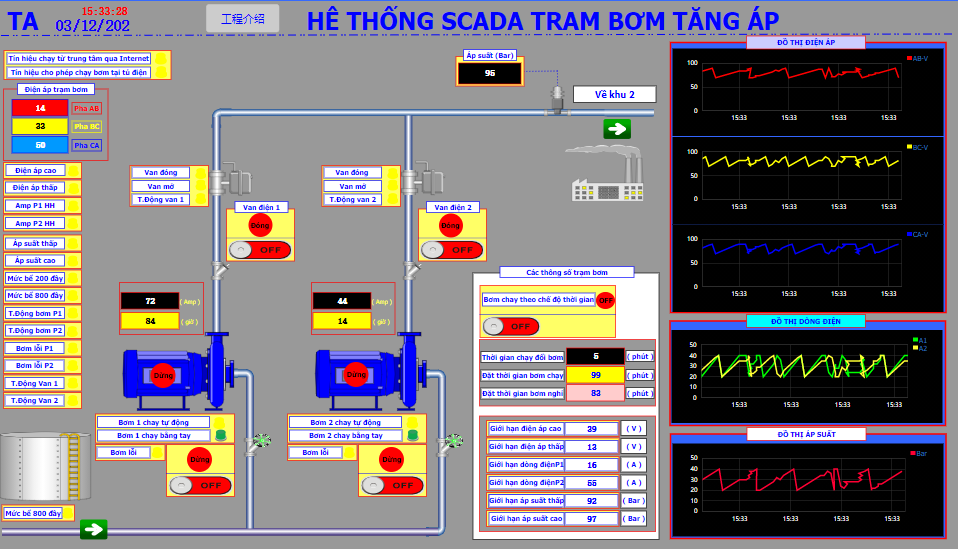

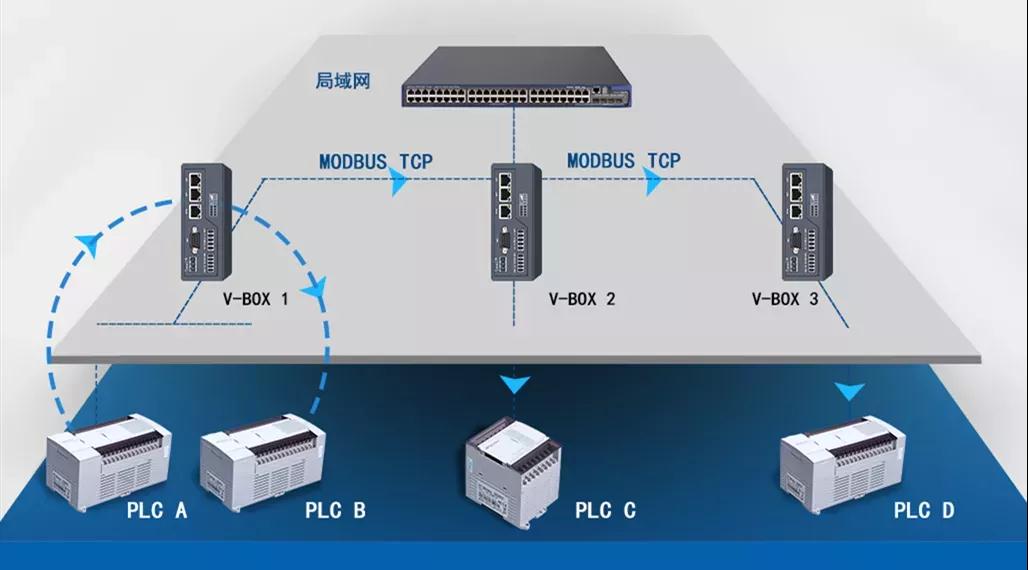

Con el desarrollo de la industria de IoT, el control de bombas ya no se limita al trabajo manual. El control remoto de la bomba de agua utiliza sensores para detectar el nivel de agua en tiempo real para controlar el inicio o la parada de la bomba de agua. Si el sistema maestro-esclavo no detecta la señal del latido del corazón del otro durante la operación, el comando de inicio ejecutado actualmente se detendrá y se emitirá una alarma. El dispositivo V-BOX realiza la transmisión de datos a través de la red 4G para lograr una retroalimentación en tiempo real de la información de alarma.

Process Requirements

Two sets of control systems,each of which is 1 master and 4 slaves,collect the liquid level of the pool centrally,and remotely control the start and stop of the pumps of each slave station to achieve centralized control management. Although the process is simple,a variety of external factors need to be considered. When writing a program,a variety of possible situations need to be considered,and an early warning prompt is provided on the interface. such as:

●If there is a problem with the liquid level at the centralized end,it is necessary to judge whether the sensor is disconnected.

●If the device data is interrupted,it is necessary to judge whether the V-BOX on the centralized end is offline or the PLC stops running.

●If the device data cannot be updated,it is necessary to judge whether the V-BOX on the control end is offline or the PLC stops running.

Case Analysis

In general,the solution is to exchange data between 4 PLCs through V-BOX. The centralized control end selects the more powerful Smart V-BOX S-4G,the control end selects the cost-effective E-4G,and the control system PLC selects LX3V- 0806MR-A,select LX3V-2ADI-BD for analog data acquisition,select PI3102i for HMI of control interface.

Program Introduction

1. First,you need to plan the data parameters that the system needs to interact.

2. Address correspondence: data is mapped in double word shaping. For example,in the control address given by the host to the slave,the low byte has heartbeat data and real-time data; the high byte has control words,including start,stop and fault reset. The address mapping function of V-BOX is to write the constantly changing data in real time and effectively,and can obtain bidirectional real-time data read and write operations to ensure the success of the mapping.

3. The program segment of the host PLC: If the host PLC fails to receive the heartbeat change from the slave PLC for a certain period of time,it will output an alarm.

4. The program segment of the slave PLC: The slave PLC fails to receive the heartbeat change of the master PLC for a period of time,and the slave PLC stops the equipment.

HMI Screen