1.Introduction

Automatic color pen assembly machine is that automatic assembling watercolor pen, pen and other types of pen , with reverse, pen mouth, rice head, copper head, fiber head, big hat, hat and complete assembly process Function.

2.Process requirements

Each vibration table sends accessories, the spindle drives each axis to move forward , through the spindle encoder to locate the assembly process action of different interval.Which could test defective product, and automatic nesting for defective products.

3.The program

The control system used WECON LEVI-700LK hmi, LX3V-2416MT4H plc

The main program is as follows: PLC communicate with inverter , control the speed. Using the spindle encoder as positioning of the angle working interval. encoder as the angle of work range positioning, using high-speed counter C252 (with Z phase), and the E-cam instruction to realize the action distribution.

4.The introduction of project

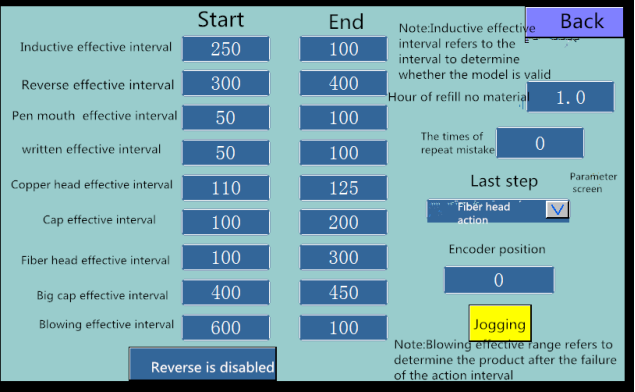

HMI program: the screen is mainly the action interval of the process steps, the equipment, such as the location of important parameters.

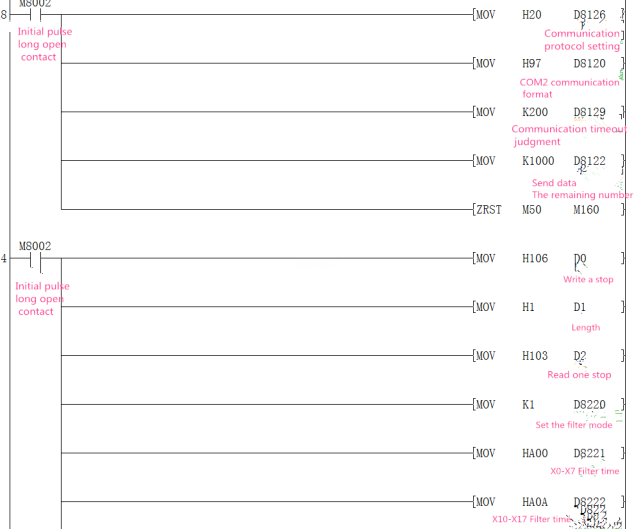

The part of PLC program:

Inverter communication and filter setting program

E-cam program

5.The summary of program

1, The system depends on the encoder interval positioning, which mainly rely on ABSD instructions. The operation of this instructions is a multi-segment comparison, which realizes E-cam control. The form, the counter, etc. are set in absolute manner.

2, Additional offset count, residual tracking program, making the system control program more reliable.

6.The photo of

project