Introduction

The marble edging machine is divided into two parts: thickness and feeding: after calibrating the thickness, it can move to the set thickness automatically; the feeding system has eight grinding heads, the first three positions are unchanged, and the last five are going up when the marble is in the right position, but falling when leave the position, it can accommodate up to 35 marbles in the system at the same time. The grinding head can be chose whether to join the system or not.

Process requirements

The feeding system remembers the head and tail position of each piece of marble through the stroke switch and the encoder, and programs the grinding head to control each grinding head. The thickness is controlled by the encoder.

Solution

The control system mainly consists of the WECON HMI LEVI-102L, and the PLC is LX3V-3624MR.

Program introduction

HMI project

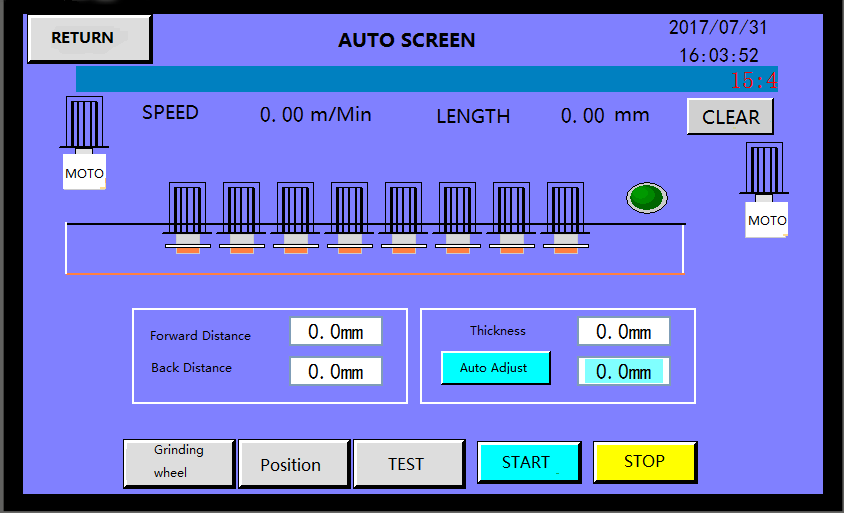

1, the main screen

Display the current state of the system and the real time action, user could also adjust the thickness in real time.

2.grinding head position setting

3.Pulse setting

PLC programming

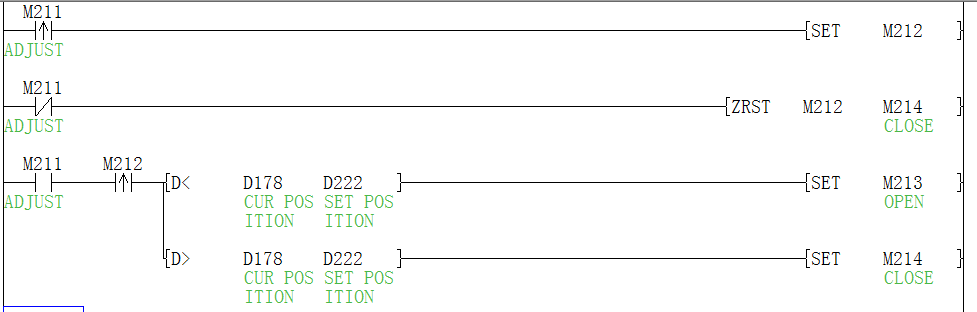

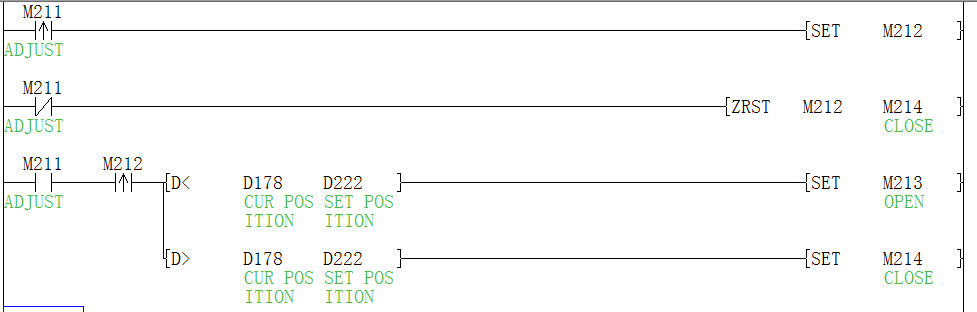

1.Thickness adjustment

2. Marble position memory

When the travel switch is triggered( rising signal or falling signal), the position will be remembered, then compared with the real-time pulse to know the position of each grinding head, then decides the next action.

Summary

The system can be operated manually and automatically. The automatic operation is fast and stable, and supports continuous processing of multiple pieces of marble at the same time.